- Fully automated hardness testing

- Rockwell, Super-Rockwell and Brinell (HBT)

- According to DIN EN ISO 6508 and ASTM E18

- Control over SPS (incl. GOOD/BAD rating)

- Implementable in production plants

- Very flexible mounting options

The hardness testing machines are designed for production support and 100%-Checks for higher quantities. Owing to the new design you are able to integrate it into production plants without any problems.

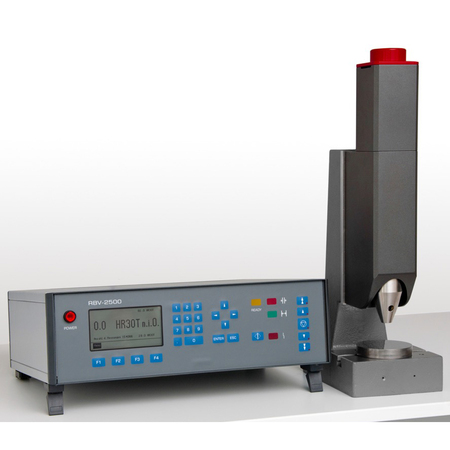

Every machine consist of the hardness test module and a separated control unit, which can be built into a electric cabinet.

Versions for every Rockwell-procedure are part of the program.

The Brinell-machines use a modified procedure to scale the penetration, since the optical measuring of the indentation isn't useful in a fast, automated testing.

The test load is regulated and scaled steadily during the load application. The result is a high accuracy with a fast measuring speed.

The test cycle will be triggered over the Start-input, after the test object is positioned. The standardized test cycles lasts approx. 20 Sec. When the test is completed, the Ready-output signalizes, that the test object can be removed. The test result will be evaluated according to the adjusted borders and the switched outputs are set. The hardness value can be requested over USB, RS232 Interface or TCP/IP-LAN.

| Hardness scale | Rockwell and Super-Rockwell-Procedure, others on request |

| Test load (Rockwell) | Chooseable from 15-150 kg |

| Hardness resolution | 0,1 HRC |

| Lifting | 20 mm |

| Test cycle | Approx. 20 Sec. |

| Power supply | 85-264 V / AC |

| Dimensions | 75 mm x 120 mm x 420 mm |

| Installation | Tapped holes on the back side |

| Control unit | 19″-Case, 3 HE |

| Connection to SPS | Switch-output, (potential-free) |

| Interface | USB, RS232, Ethernet |

| Display | Color-LCD |

- Rockwell-Module

- Control box

- Power cable

- Manual

- Certified test blocks